We are Triknit, a new-age garment house engaged in manufacturing and exporting knitted garments situated at Tirupur, the textile epicentre of South India, We enjoy the advantage of a strategic location. We bring with us, our parent company’s rich experience of over 70 years in dyeing. Taking a cue from its extensive expertise, we at Triknit striving to carve a niche for ourselves in the competitive arena of knitwear exports.

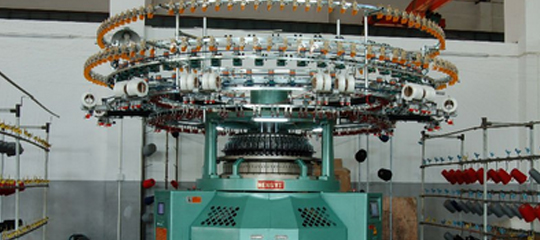

Knitting

Our knitting unit comprises the most modern machines, capable of producing a vast number of high quality fabrics. Equipped to produce a daily capacity of 10 tons, the unit manufactures knit fabrics like Single Jersey, Interlock, Rib, Auto Stripes, Loop Knit, Full Jacquard, Wrapper, etc.

Dyeing

Our dyeing division is equipped to handle dyeing of yarn, fabrics as well as garments. The yarn dyeing unit is equipped to dye up to 12 tons/day, while the fabric dyeing unit can dye 12 tons/day. We have advanced technology machine "Selavos". In keeping with our responsibility to the environment, we use only Azo-free dyes. Also, our modern Effluent Treatment Plant ensures that we are attuned to the prevalent environmental norms.

Cutting

We have an advanced cutting division that is equipped with the finest "Morgan" and "Lectra" machines. It also has the latest CAD/CAM technology and spreader to help make quicker patterns. The production capacity is almost 18,000 - 20,000 pieces per day.

Embroidery

Our embroidery unit houses with hi-tech machines that are capable of the most intricate embroidery. These include Barudan from Japan that can make up to 9 colors. We also have the Japanese Tajima chenille embroidery machines. The unit can do embroidery up to 18,000 - 20,000 pieces/day.

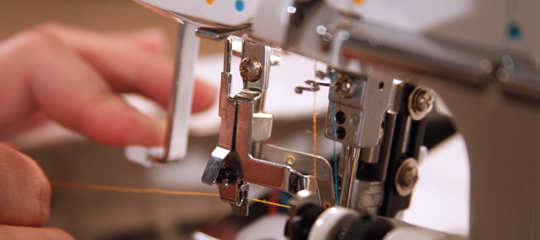

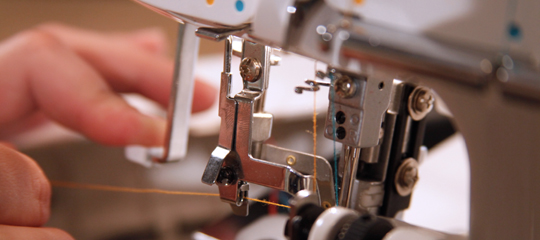

Sewing

Our stitching facility is a fine combination of the most modern oil-free machinery and dexterous personnel. Together, they are capable of producing nearly 20,000 pieces per day.

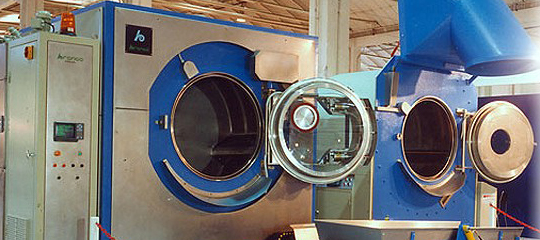

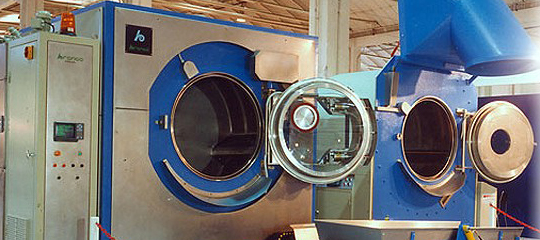

Washing

Our garment washing unit facilitates different types of washes like Stone wash, Enzyme wash, Acid wash, Silicon wash, Bio-polish, Leather finish, etc. It has a capability of 3 tons/day.

Printing

We have a contemporary printing division in-house to facilitate the latest and trendy designs that leave a lasting impression on our garments. We have the Rotary machine that can print up to 8 colours and the Chest printing machines for prints like Pigment, Discharge, Non-PVC, Foil, Flock, High-density, etc..

Finishing

Our compacting machines come in open-width as well as tubular types with a combined capacity of 10 tons/day. For the finest finishing touch, we have peach finishing machines with a capacity of 6 tons/day. The soft touch machines are designed to give fabrics the softest feel as well as egress effects. For controlling the moisture in fabrics like Lycra, Polyester, Yarn-dyed stripes, we use advanced "Santex" stinger machines with a capacity of 6 tons/day.

Infrastructure

TRIKNIT and its group/associates are in businesses of garment manufacturing, dyeing, knitting, compacting, stenting, mercerizing, printing, finishing, CAD/CAM based cutting systems with spreader, embroidery, various washing, and value addition of cotton, fiber, yarn and fabrics

The firm has modern and computer aided hi tech sampling facilities with appropriate Designing, color matching, and screen tools. It is able to deliver approval designs and matching samples in less than 24 hours.

The processing facility is located over an area of 65000 sq ft in a well-equipped industrial building with all required utilities in heart of Tiruppur, India’s Dollar City with a 100% captive effluent treatment plant.

The production area is very well ventilated and has a staff and worker canteen along with tertiary medical care facilities in-house. There is an adequate installed capacity for fabric pretreatment and dyeing machines comprising of Jets, Jiggers, JT, Mercerising, Drum washers, Flatbed Printing, Rotary Printing, Polymerizing, Cold Padding, Washing, Finishing, Compacting along with Hand Printing and Spray Printing facilities under the same roof.

Above all, our members are our greatest asset and biggest differentiator. We are passionate about delivering results to our customers / buyers. All TRIKNITIANs are direct and always straightforward—even if it means telling an uncomfortable truth. We are ambitious and impatient for success, and yet down-to-earth and most approachable. In short, TRIKNITIANs are not only the kind of people you would love to work with, but they are also titans you would want to socialise with outside work. TRIKNIT encourages you to take every opportunity to interact with our members and witness the vibrancy and warmth of the office in the person.